Cogeneration: A method of energy production that generates both electricity and heat within a single system.

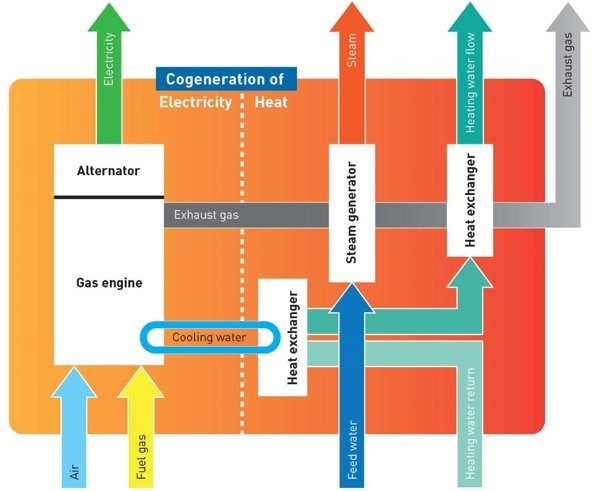

Cogeneration System: A system that performs the cogeneration process.

Primary Energy Source: The fuel used in a cogeneration system (natural gas, biomass, coal, etc.).

Thermal Engine: An engine that converts the chemical energy of fuel into mechanical energy.

Generator: A device that converts mechanical energy into electricity.

Heat Recovery System: A system that makes waste heat from the thermal engine useful.

Heating: The process of meeting the heat requirements of buildings and processes.

Cooling: The process of meeting the cooling requirements of buildings and processes.

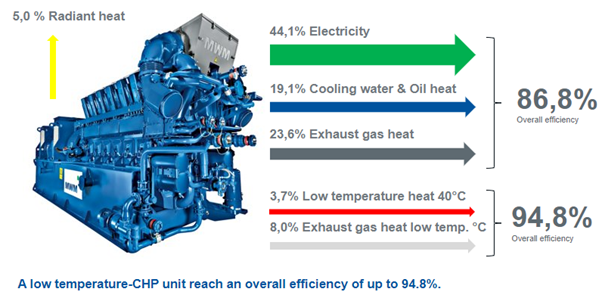

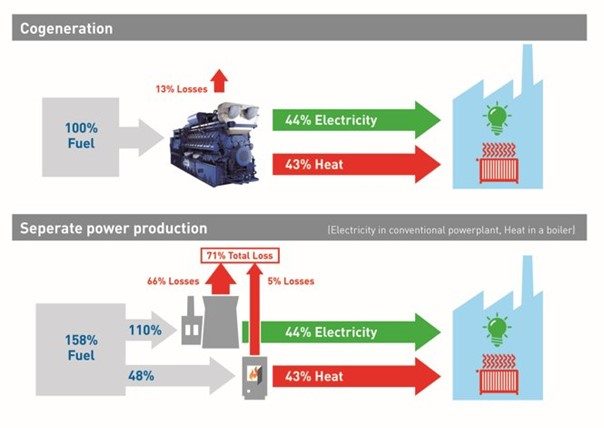

Efficiency: A measure of how effectively a system converts input into output.

Greenhouse Gas Emission: The release of gases into the atmosphere that cause climate change.

Energy Savings: Doing the same work using less energy.

Cost Savings: Saving money through energy savings.

Return on Investment (ROI): The profit gained from an investment.

Payback Period: The time it takes to recover the cost of an investment.

Government Incentives: Incentives provided by the government to businesses that invest in cogeneration systems.